Baghouse Dust Collector

Dust Collection System

Baghouse Dust Collector

Dust Collection System

A dust collection system is essential for effective functioning in almost every industry facility. The operation, reliability and efficiency of the dust collection systems have a direct impact on facility's profitability, e.g. production downtime and energy consumption costs. In light of this, it is crucial to choose dust collection systems suitable for specific applications.

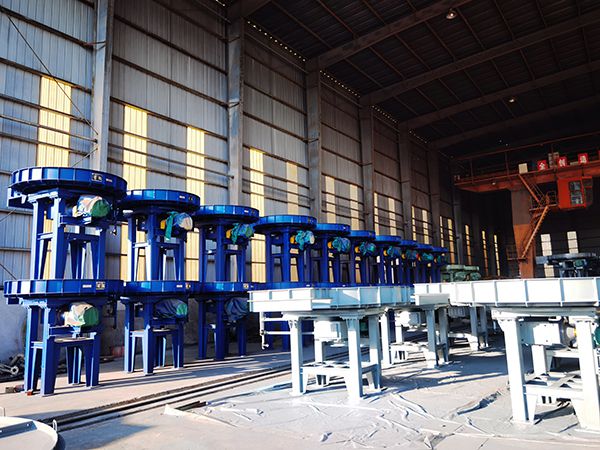

Zhongding is specialized in designing and manufacturing baghouse dust collector that has been widely applied in metallurgy, cement, steel, chemical, electric power and other industrial areas.

- Dust removal efficiency: ≥ 99.99%

- Air leakage rate: ≤ 2%

- Design resistance: ≤ 1500Pa

- Inlet and outlet temp. drop: ≤ 10 ℃

- Compact structure, reasonable layout, and high dust removal efficiency.

- The baghouse dust collector is designed with anti-corrosion material for handling high corrosive gases in the hazardous waste industry, with good corrosion resistance.

- Adopting multiple sealing and insulation measures, with low air leakage coefficient and good insulation performance. The temperature difference between the inlet and outlet of the dust collector is small, ensuring that the system operates at temperatures above the dew point.

- Select high-strength and corrosion-resistant cage bones to ensure the service life of the filter bag.

- According to different working conditions, flexible selection of PTFE+PTFE membrane filter bags, dioxin removal catalytic filter bags or denitrification filter bags can play a role in dust removal, acid removal, denitrification, and the removal of dioxins and heavy metals.

The main components of a bag filter are: upper box (purification chamber), middle box (bag chamber), ash hopper and frame, pulse cleaning system, and ash discharge system.

-

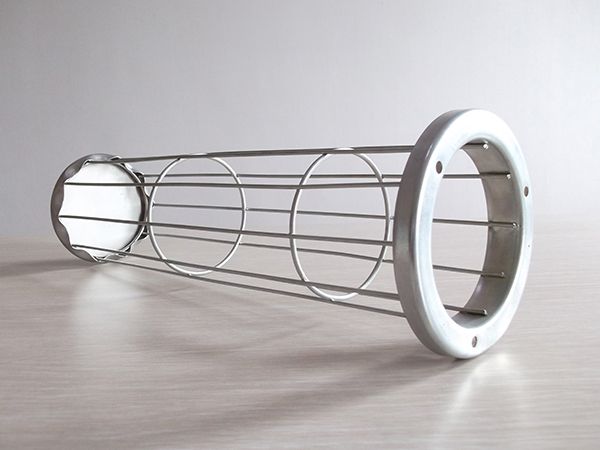

- Filter Bag Cage Filter bag cage, also known as dust collector cage or baghouse filter cage, is formed by one-time welding with specialized equipment. Learn More

-

- Disk Feeder Disk feeder’s operation stability directly affects the output quantity and quality of steel production. Learn More

-

- Rotary Kiln Zhongding is a leading non-standard environmental protection equipment manufacturer in China. Learn More

-

- Baghouse Dust CollectorA dust collection system is essential for effective functioning in almost every industry facility. Learn More