Searching for hazardous waste disposal solutions?

Our sludge drying and incineration technology has been successfully implemented in multiple projects, effectively solved challenges in sludge drying and incineration, such as high difficulty, pollution, and cost. Our solution prevents secondary pollution during the incineration process, which is a breakthrough in sludge treatment and disposal technology. The sludge drying system includes fluidized bed dryer, cyclone dust collector, flue gas condenser, pressure-boosting fan, etc.

-

- System Components Sludge receiving, storage and transportation system, high-pressure belt dehydration system, sludge drying system, sludge incineration system, waste heat utilization system, flue gas purification system, etc. Learn More

Our Integrated Sludge Fluidized Bed Drying and Incineration Equipment

- The equipment is developed by collaboration with Southeast University, School of Energy and Environment. It combines the advantages of sludge treatment technologies from worldwide and is tailored to the unique characteristics of sludge in China.

- By integrating the sludge drying and incineration systems, the design maximizes the use of waste heat from the incineration system, resulting in lower moisture content requirements for wet sludge.

- Over the years, our technology has been successfully applied in numerous projects, effectively solved issues such as processing difficulty, pollution and high cost associated with sludge drying and incineration. By preventing secondary pollution during the incineration process, our solution brings a groundbreaking advance to sludge treatment and disposal technology.

- Low moisture content requirement for incoming sludge The system can handle various types of sludge, including municipal and industrial, with an incoming sludge moisture content of up to ~80%.

- Inert flue gas ensures safe drying at high-temperature By fully utilizing the inert flue gas generated during incineration, circulating it within the system, the risk of sludge dust explosions during high-temperature drying is effectively avoided, safety and reliability are thus enhanced.

- Efficient and energy-saving drying and incineration processes The insulated furnace ensures self-sustaining incineration of low-calorific-value sludge. With a minimum calorific value of 1000 kcal, the sludge is allowed for self-sustaining incineration at above 850℃ without auxiliary fuel. Waste heat utilization is optimized with boiler exhaust gas temperature around 200℃, achieving high energy-saving and environmental protection efficiency.

- Various models for different requirements Customized non-standard design is offered, to meet small, medium, and large-scale sludge treatment needs. Up to 20-1500 T/D single processing line capability, up to 80-82% sludge moisture content.

We offer integrated sludge drying and incineration solution according to your needs.

| Device | ||

| Dual Shaft Screw Conveyor for Receiving Hopper | Conveying sludge with 80% moisture content | 2 |

| Screw Conveyor (for Filter Press Discharge) | Conveying sludge with 65% moisture content | 1 |

| Stacked Screw Machine | Designed capacity: 100-150 kgDS/h | 1 |

| Drying Machine | Designed capacity: 50t/d (65% moisture content sludge), (35-40% moisture content sludge, with sludge inlet dispersing device) | 1 |

| Fluidized Bed Incinerator | Circular furnace with an inner diameter of 1.85 meters and a net height of 8.5 meters | 1 |

| Refractory Material | Inner side: wear-resistant castable, middle: insulating castable, outer side: aluminum silicate fiberboard Thicknesses (respectively): 120mm, 130mm, 100mm | 1 |

| Waste Heat Boiler (with Air Preheater, Reheater, and Economizer) | Flue gas inlet temperature: 900°C; economizer outlet temperature: 200°C; evaporation capacity: 2t/h; saturated steam outlet pressure: 1.0 MPa, temperature: 180°C; with boiler drum, shock wave soot blower, waste heat boiler ash discharge system, periodic blowdown expansion tank, insulation, castable, ash discharge device, and steel structure | 1 |

| High-Temperature Air Preheater | Ambient temperature; outlet temperature: 450°C | 1 |

| Flue Gas Reheater | Low-temperature flue gas inlet volume: 1500 Nm3/h; inlet temperature: 170°C; outlet temperature: 250°C | 1 |

| Dry Reaction Tower | Double loop; Φ426xΦ720-H10000 | 1 |

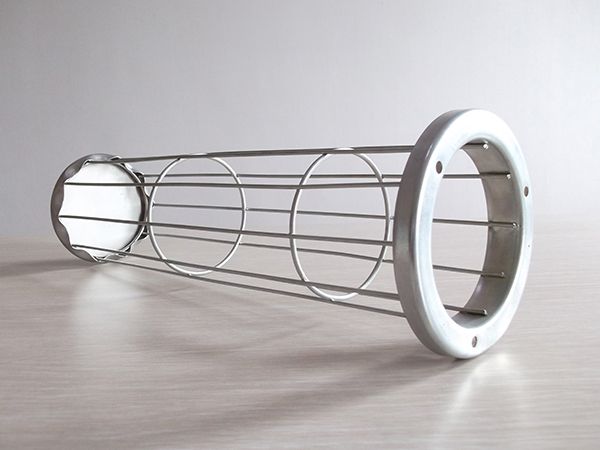

| Primary Baghouse Filter | Inlet flue gas temperature: 200°C; dust concentration: 5~8g/Nm3; filtration velocity: ~0.6m/min; filtration area: 247m2; inlet and outlet temperature difference ≤10°C; outlet dust concentration <20mg/Nm3; with reverse air bag, filter bag and cage, pulse valve, electric heating, screw ash discharge machine, unloading valve, and external insulation (thickness: 150mm), etc. | 1 |

| Secondary Baghouse Filter | Inlet flue gas temperature: 170°C; filtration velocity: ~0.8m/min; filtration area: 133m2; inlet and outlet temperature difference not greater than 10°C; outlet dust concentration less than 10mg/Nm3; with reverse air bag, filter bag and cage, pulse valve, electric heating, screw ash discharge machine, unloading valve, and external insulation (thickness: 150mm), etc. | 1 |

| Induced Draft Fan | Operating temperature: 170°C; temperature resistance: 200°C; pressure: 10 kPa; variable frequency motor; SKF bearings; with drain, inspection hole, anchor bolts, and rain cover | 1 |

| Desulfurization Tower + Chimney | Integrated design; minimum total height: 45m | |

| Desulfurization Tower | Empty tower internal circulation structure; temperature: 170°C; dimensions: Ø1.02×12m; with three-stage spray heads, two-stage demisters (FRPP, 200mm-thick each stage) and accessories; desulfurization efficiency above 97% | 1 |

| CEMS | Fourier transform infrared (FTIR) gas analyzer | 1 |

The chimney is included at the top of the wet desulfurization tower. The designed height is 45m (including tower height), meeting the requirements of GB 18485 standard by People's Republic of China government.

-

- Integrated Sludge Drying and Incineration Project in Jiangying, Jiangsu

Phase I capacity (per unit) 150T/d (TW60%), on service in 2019

Phase II capacity (per unit) 750T/d (TW60%), on service in 2022 Learn More

Our Waste Handling Equipment

-

- Filter Bag Cage Filter bag cage, also known as dust collector cage or baghouse filter cage, is formed by one-time welding with specialized equipment.

-

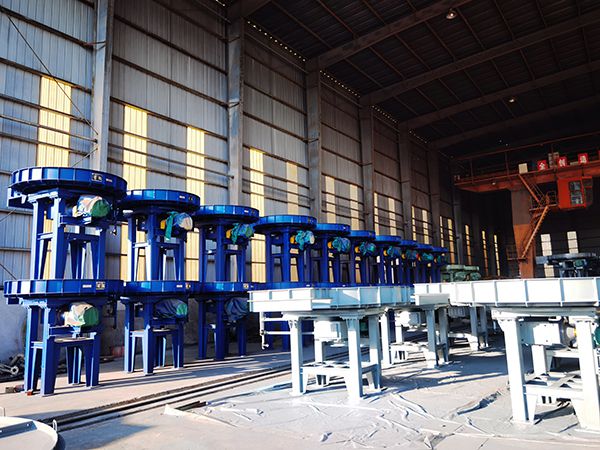

- Disk Feeder As a professional disk feeding system manufacturer, Zhongding is experience in researching, developing and producing for over 30 years.

-

- Baghouse Dust CollectorZhongding specializes in the development, design, and production of dust removal and dust collection equipment, which are widely applied in various industries such as metallurgy, cement, steel, chemical, power sector, etc.

-

- Rotary Kiln Zhongding is a leading non-standard environmental protection equipment manufacturer in China. Our direct-fired rotary kiln is known for its durability, efficiency, and quality.