Searching for hazardous waste disposal solutions?

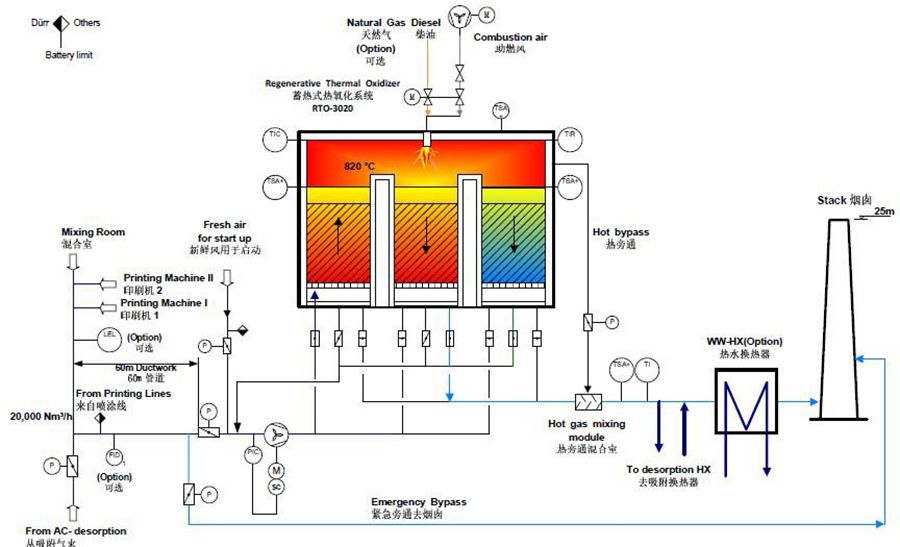

Regenerative thermal oxidizer (RTO) is an energy-efficient air pollution control equipment used for treating low to medium concentration volatile organic waste gases. The basic principle of the RTO is to oxidize the organic components in the exhaust gas to generate CO2 and H2O at high temperatures, achieving a high removal rate (99.5%). This device incorporates a regenerative heat exchanger, which contributes to energy-saving oxidation due to its high heat recovery rate (> 90%).

Structure

- Resin adsorption and biological deodorization technologies from Nanjing University, chemical scrubbing using activated carbon (fiber) adsorption-desorption + condensation recovery.

- zeolite + RTO regenerative combustion, CO catalytic oxidation.

- Sealing Technology: Steel-to-steel hard sealing technology + high-frequency and high-speed switching.

The rapid switching time of 0.8 seconds minimizes heat loss. - Safety Technology: 5 dual-systems + over 20 safety interlocks.

5 dual-systems: electrical integration, software-hardware integration, dual shut-off valves, dual probes, and dual pipeline. Multiple safety designs.

Detection is carried out at more than 20 points to eliminate any safety hazards at the forefront, ensuring the eradication of all dangers at the source. - High-efficiency Heat Storage Technology: a thermal efficiency of 95-97% is achieved by controlling heat storage material quantities, stacking methods, and insulation.

Technical features:

The quantity of heat storage materials is the foundation of thermal efficiency.

Tight stacking ensures no air leakage.

Excellent insulation minimizes heat loss.

Two chambers are dedicated to heat exchange, while the third chamber has no heat storage material (reducing heat loss, more heat storage chambers results in more heat loss points). - Negative Pressure Blowdown Technology: apply a fixed negative pressure capture chamber without heat storage materials for blowdown, energy-saving.

Technical features:

Utilizes negative pressure from the system for blowdown, no need for continuously operating blowdown fans, thus to reduce electricity consumption.

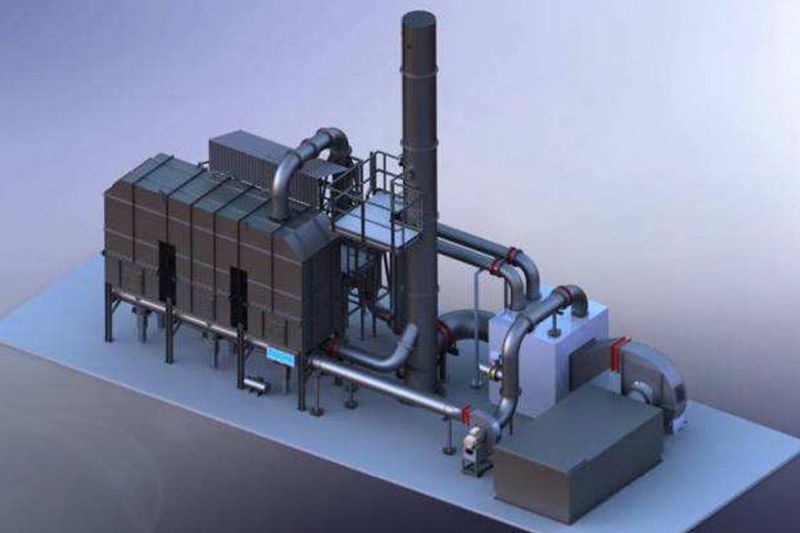

Smart RTO System - Product-oriented design

Product-oriented design philosophy: providing customers with top-tier products and services through professional engineering technologies and comprehensive solutions.

Product Instead of Project

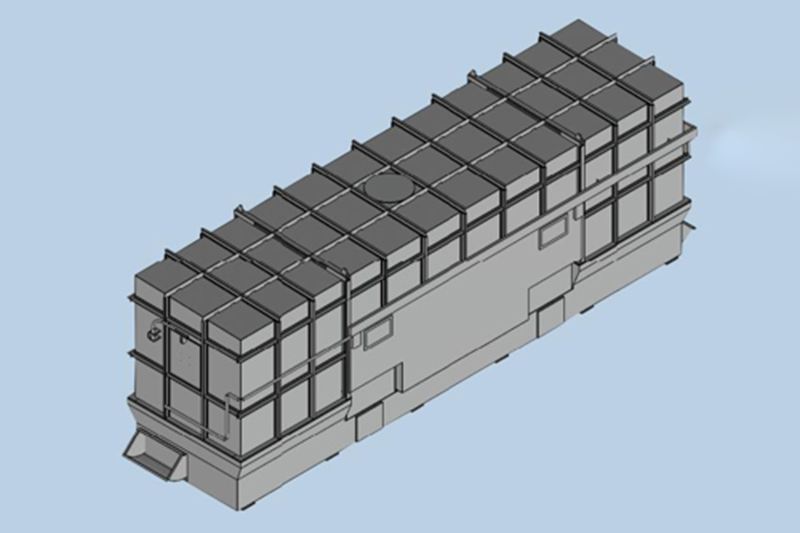

Standardization - Series of products

Modularity - Flexible customization options

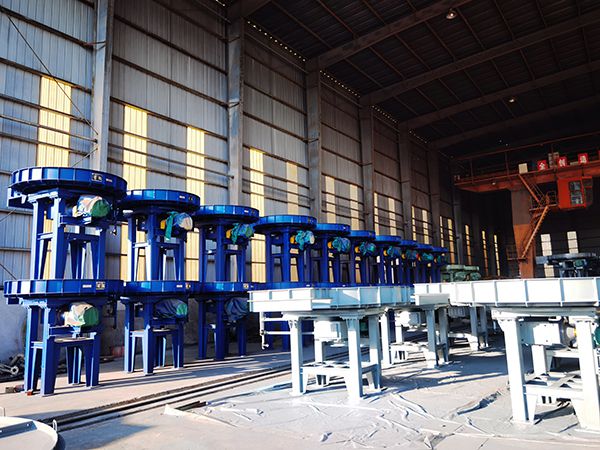

Smart RTO System - Factory Pre-commissioning

Transported and lifted as a complete unit.

Product-oriented assembly in factory

Pre-commissioning in factory

Transported as a whole unit

Overall lifting and installation

Smart RTO System - Plug and Play

Once Smart RTO is installed at the predetermined location, the system can be quickly set up and put into operation by following instructions. Simply connect the intake and exhaust pipelines, as well as the fuel, compressed air, and power supply following instructions, the system will quickly complete all necessary settings and be ready for operation.

Smart RTO System - Easy Maintenance

Modular Design: Flexible for Various Needs

Modules: smart RTO rapid cooling + alkaline washing tower chimney buffer tank + exhaust air inlet duct

| Smart RTO - Options | |

| Specifications | Smart series |

| Air volume (Nm³/H) 1000~30000 | |

| Basic parameters | Emission concentration (mg/Nm³) < 20 |

| Heat exchange efficiency >95% | |

| Buffer tank (optional) | |

| Hot bypass (optional) | |

| Chimney (optional) | |

| Optional devices | Waste solvent incineration device (optional) |

| LEL detection device (optional) | |

| FID online concentration measurement system (optional) | |

| Surplus heat recovery method | Water heating (optional) |

| Air Heating (optional) | |

| Heat conducting oil (optional) | |

| Quenching (optional) | |

| Electricity generating (optional) | |

| Note: Specifications listed above are of typical models, for actual specifications please see the technical contract. | |

Hazardous waste disposal centers, pharmaceuticals, petrochemicals, packaging and printing, VOCs of battery, etc. industries, odorous exhaust gas treatment

-

- RTO System Zhongding's RTO systems have been applied in over 300 cases, including projects of Yangtze River Pharmaceutical Group, Fosun Pharma, Sinopharm, Xinpuchem, Dongjiang Hazardous Waste Disposal Center, Jinling Gold Foil Group, Nanjing Cigarette Factory, Yankuang Lunan Chemicals, CNOOC, etc. Learn More

Our Waste Handling Equipment

-

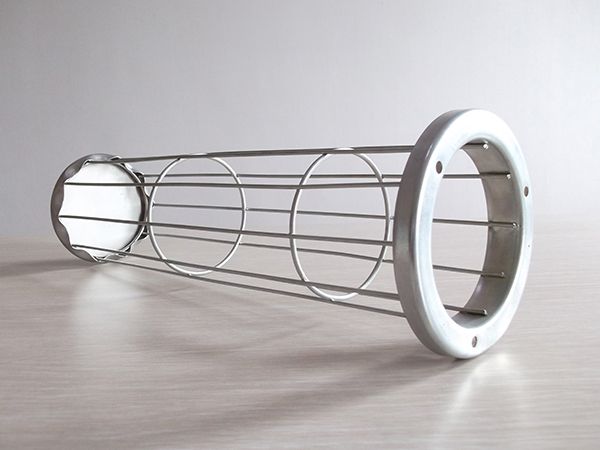

- Filter Bag Cage Filter bag cage, also known as dust collector cage or baghouse filter cage, is formed by one-time welding with specialized equipment.

-

- Disk Feeder As a professional disk feeding system manufacturer, Zhongding is experience in researching, developing and producing for over 30 years.

-

- Rotary Kiln Zhongding is a leading non-standard environmental protection equipment manufacturer in China. Our direct-fired rotary kiln is known for its durability, efficiency, and quality.

-

- Baghouse Dust CollectorZhongding specializes in the development, design, and production of dust removal and dust collection equipment, which are widely applied in various industries such as metallurgy, cement, steel, chemical, power sector, etc.