Searching for hazardous waste disposal solutions?

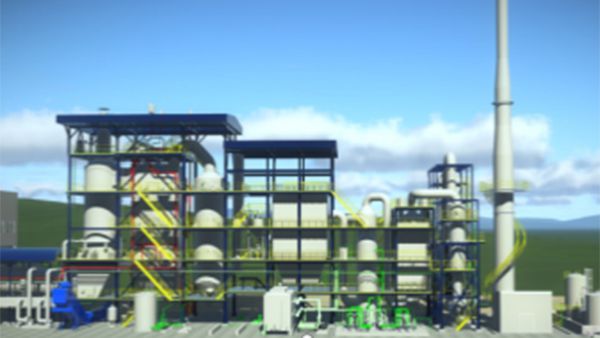

Tailored to your specific waste and facility requirements, we provide robust, tested, and secure rotary kilns and corresponding equipment to ensure safe operation and environmental sustainability.

In 2014, Zhongding has established partnership with the Kawazu team from Japan Benenv Co.,Ltd., introduced Japan's state-of-the-art incinerator technology, process calculation package and simulation software. We have established close and stable collaboration with top-tier companies and design institutes in hazardous waste incineration industry in China, and for now, we’ve provided over 40 large-scale hazardous waste incineration disposal systems.

When designing incineration systems, technologies are chosen considering not only to handle current processed materials, but also adaptability to future changes in material form, calorific value, etc. We reserve inlets for gas waste to make it easy for adapting corresponding devices. Our control system is designed with ample redundancy, enabling convenient expansion.

Due to the high temperature of the rotary kiln, besides conventional hazardous waste, our system is also able to handle highly toxic substances such as cyanides, rodenticides, POPs, and PCBs. This broad-spectrum performance could provide good sustainability to your project.

Based on the experience gained from operating hazardous waste incineration facilities, we have optimized the design in several aspects, resulting in a compact, rationally laid out system with a small footprint, easy maintenance, and a streamlined and reasonable process flow:

- By cooperating with experts from Japan, we’ve introduced advanced technologies, process calculation package and simulation tools, providing strong theoretical and data support for design, develop and manufacture, all specifications are traceable.

- 3D and PID design are available if needed. We use 3D forward design for detailed works on equipment, steel structure, piping, structure, HVAC, and support bracket, achieving BIM digital delivery for the entire project.

- Design Verification by Simulation

Upon request, we’re able to conduct a full-system fluid model test for the project, simulating temperature, flow rate, and pressure throughout the system process, analyzing the feasibility of the design, and providing rationalization suggestions.

Waste Treatment Process: Feeding - Incineration - Waste Heat Utilization - Flue Gas Purification and Emission

-

- Rotary Kiln Incineration System Rotary kiln incineration system is designed for the incineration and treatment of hazardous waste, medical waste, and general industrial solid waste. It is capable of handling hazardous waste in various forms such as solid, semi-solid, and liquid. Our advanced system ensures that the combustion process meets flue gas emission standards, resulting in high environmentally friendliness. Learn More

Design, Manufacture, Installation, Commissioning, and Operation - Ensuring the Right Solution for You

- We’re integrated with the abilities of design, manufacture, installation, commissioning, and operation, equipped with various advanced devices, and have an annual production capacity of ¥500 million.

- All equipment designs undergo continuous improvement and optimization across projects, striving for perfection. Manufacturing and acceptance processes are adhering to standards and requirements from top-tier experts during.

- All structural components undergo shot blasting rust removal (Sa2.5 level), ensuring rust prevention capability for over 6 years.

- We maintain an ample supply of commonly used spare parts, providing solid support for the operation of each project.

- Our highly skilled installation, design, and operation teams are able to reasonably arrange the installation and commissioning progresses of each project; promptly address and resolve various issues that may arise on-site; and ensure that the system meets designed specification, capacity, and operates safely.

We are committed to providing online support within 12 hours for any assistance required, resolving technical issues, and, when necessary, dispatching technicians on-site for problem shooting.

Devices (Configured according to your actual needs – here’s a list devices of a sample project we have done with 100t capacity)

| Device | Specification | Quantity |

| Plate Feeder | Conveying capacity: 25m3/h, frequency conversion, with hopper and uniform feeding device | 1 |

| Kiln Head Bucket Elevator | 400kg/cycle, 10 cycles/h, manual loading, 240L standard trash can | 1 |

| Crusher | Double-roller shear crusher, capacity: 8-12t/h, steam fire extinguishing protection | 1 |

| Rotary Kiln | Φ4200×L16000, inclination: 2°, rotational speed: 0.12~0.6r/min. | 1 |

| Secondary Combustion Chamber | Cylinder Φ5800×H15790, emergency chimney: Φ1488×H10500 | 1 |

| Waste Heat Boiler | Evaporation capacity: 12.3t/h, saturated steam outlet pressure: 1.6MPa, temperature: 201°C, flue gas temperature: inlet 1150°C, outlet: 550°C, with boiler drum, shock wave soot blower, slag remover, periodic blowdown expansion tank, continuous blowdown expansion tank, and insulation | 1 |

| Quench Tower | Ø7200×8200×H18500, with ash discharge valve, air distributor, dual-shaft crusher, and accessories | 1 |

| Dry Deacidification Tower | Φ2000×H10000 | 1 |

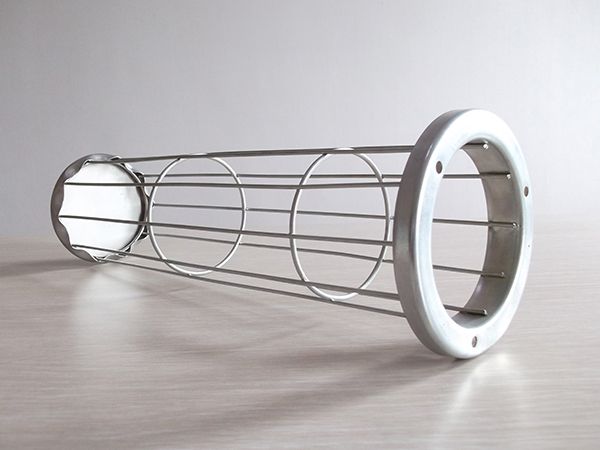

| Baghouse Filter | Filtering area: 2351m2, with 2 reverse air bags, 780 filter bag sets, air cannon, 78 pulse valves, electric heating, and external insulation | 1 |

| Primary Deacidification Tower | Ø3100×13020, with tower internals, high-temperature and corrosion-resistant fiberglass cylinder, exterior color should match the main equipment | 1 |

| Secondary Deacidification Tower | Ø3100×16020, with tower internals, high-temperature and corrosion-resistant fiberglass cylinder, exterior color should match the main equipment | 1 |

| Primary Deacidification Pump | Horizontal centrifugal pump, Q=180m3/h, H=35m | 2 |

| Secondary Deacidification Pump | Horizontal centrifugal pump, Q=180m3/h, H=35m | 2 |

| Induced Draft Fan | Q=90800Am3/h, P=11000Pa, frequency conversion | 1 |

| Chimney Steel Inner Liner | Ø1400×H75000 | 1 |

Since 2014, Zhongding has offered one-stop rotary kiln hazardous waste incineration solutions for 45 customers, assisting them in solving problems of hazardous and medical waste disposal.

-

- Hazardous Waste Treatment System After introducting rotary kiln technology and software from Japan in 2014, Zhongding has established 45 rotary kiln-based hazardous and medical waste treatment centers. Learn More

Our Waste Handling Equipment

-

- Filter Bag Cage Filter bag cage, also known as dust collector cage or baghouse filter cage, is formed by one-time welding with specialized equipment.

-

- Rotary Kiln Zhongding is a leading non-standard environmental protection equipment manufacturer in China. Our direct-fired rotary kiln is known for its durability, efficiency, and quality.

-

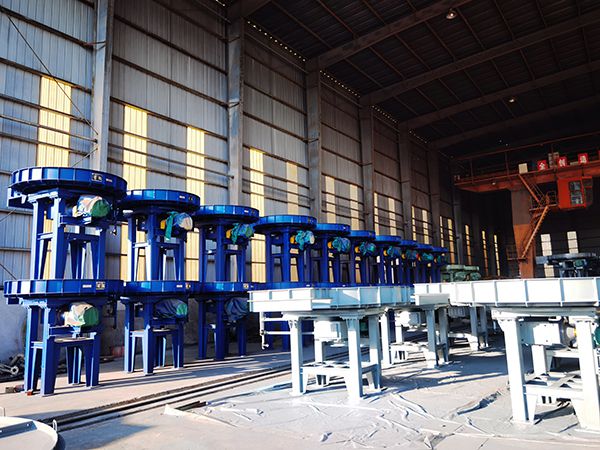

- Disk Feeder As a professional disk feeding system manufacturer, Zhongding is experience in researching, developing and producing for over 30 years.

-

- Baghouse Dust CollectorZhongding specializes in the development, design, and production of dust removal and dust collection equipment, which are widely applied in various industries such as metallurgy, cement, steel, chemical, power sector, etc.